Nowadays, Dutch legislation and even international a minimum fire resistance time of 60 minutes for office buildings, public spaces and large buildings is required. It is important that these buildings are well protected in order to slow down the fire and heat in case of a fire and thus gain evacuation time. This ensures a safe environment. A fire-resistant coating offers a solution.

Let's clarify the above through a visualization: What is the difference between the two buildings in the photos below?

Building 1

Building 2

An understandable answer will be: “They are different types of buildings.” That's true, but there is another important, invisible difference. The building on the right has been treated with a fire-resistant paint (because this is a large building). This is not visible, but in case of a fire the added value of a fire-resistant coating becomes clearly visible. We explain how.

A fire-resistant paint or fire-resistant coating is made up of several layers and is applied to a construction to protect it against fire for longer. In case of a fire, the paint layer swells due to the extreme heat. As a result, the fire-resistant coating forms an insulating foam layer. This limits the spread of the fire as much as possible. This effect leaves more time for extinguishing the fire and for possible evacuation. Due to the fire-resistant coating, it also takes longer before the construction loses its strength when a fire breaks out.

In industry we use two terms; "fire-resistant" and "fire-retardant". These are often confused with each other when they both mean different things. This difference is mainly in the tests that are carried out regarding fire safety. With 'fire or flame retardant' one looks at the fire behavior of the material. A fire class can then be linked to this. 'Fire-resistant' refers to entire spaces and (supporting) constructions. Here it is tested how long it takes for a fire to spread from one room to another (also called 'fire penetration'). For example, according to legislation, it is determined how many minutes a building must be fire-resistant.

In short, a fire-retardant product ensures that the material that has been treated catches fire less quickly. While a fire-resistant coating ensures that it takes longer before flames reach another room or a structure collapses as a result. When applying either of these, it is important to always keep one of the above goals in mind for the object; what should it do? We can provide support in the selection and application of the right coating for your metal product. Please contact us for this.

It is not only important to know which coating is best suited, but also what the advantages are. The use of fire-resistant coatings has risen sharply in recent years. This is not for nothing. This multi-layer coating contributes to safety.

✓ The insulating foam layer limits the spread of the flames.

✓ Up to 120 minutes fire resistance.

✓ Failure of the supporting structure is postponed or even prevented.

✓ The coating is finished seamlessly. This prevents moisture or dirt from penetrating under the coating which can cause weak spots.

✓ Durable: the coating lasts a long time if it is properly maintained. The product naturally has a high wear and impact resistance. Maintaining these strengths through periodic maintenance is therefore of great importance. In this way damage can be detected and repaired in time.

✓ Possibility to embellish it with RAL color of your choice. The supporting structure can thus be kept in view and even become an “eye-catcher”.

✓ Light in weight. In practice, this means that the steel construction does not have to carry many extras. This saves a lot of costs.

Increasing safety and durability are the main advantages of a fire-resistant coating. The coat of paint can last for years with proper maintenance. Just like any other coating, a fire-resistant coating also needs periodic maintenance. This means that a specialist company comes by to clean and inspect the coating, detecting any weak spots. NESTcoat can take care of this maintenance. And if damage is discovered during maintenance, we can also take care of the repair for you as a specialist in the field of damage repair to coatings. Damage to the coating reduces the added fire-resistant value, which has now become a weak spot. In order to keep the building in top condition and to meet the requirements, it is always advisable to have damage repaired in time! View our portfolio for an overview of our projects where we have done this before.

Based on the purpose of the construction, the fire resistance of a building depends on the following three elements:

1. Building length

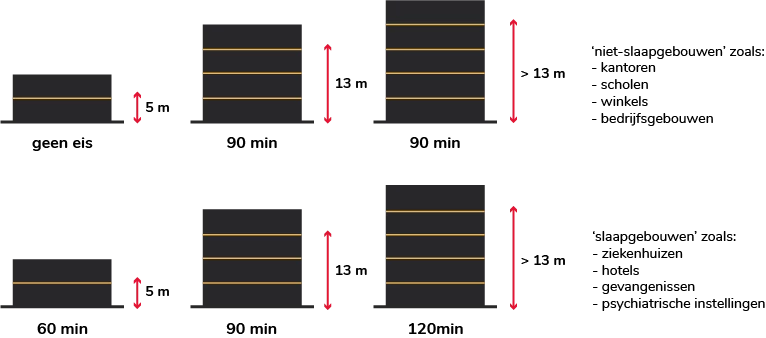

The higher and larger the building, the higher the requirements. For example: for a building five meters high, a minimum fire resistance of 90 minutes applies. But there are no exact fire-resistance laws for buildings under five meters. It is therefore advisable to always be informed by a specialist.

2. Is it a sleeping accommodation?

If the building is intended for sleeping or if it offers this possibility, a minimum of 60 minutes applies for buildings smaller than five meters. When the entire building is above 13 metres, fire resistance must be maintained for 120 minutes at all times if there is sleeping accommodation.

3. The risk factor

Sometimes a building must always be fire safe for 120 minutes. This rule applies especially to offshore industries, factories with chemical emissions or other places with a high risk factor. The legislation also applies to some public spaces such as libraries or museums with vulnerable storage.

Schematic representation of fire resistance of buildings

*Important: In general, the higher the building, the more is invested in applying a fire-resistant coating. Would you like to read more information about this? Then read this PDF about fire safety regulations in Europe.

A fire-resistant coating can be applied to various surfaces. Think of a fire-resistant coating for concrete or steel or a fire-retardant coating for a wooden surface. We focus on the applying and repairing fire-resistant coatings on steel.

Steel is known in many industries as a cost-conscious choice. Because steel is a relatively cheap type of material, a lot of surface can be built with it for a low price. Steel is also known as a strong material. It is not for nothing that many of the world's famous structures are built with this. When this material becomes hot due to heat and fire, the construction can remain upright for a long time. The construction retains its strength even longer when the material is treated with a fire-resistant coating.

To determine the costs for applying a fire-resistant coating to a steel construction, it is important to know in advance:

The finish, size of the structure and substrate all affect the final cost. The coating consists of several layers which must be applied individually. This requires more labor than applying a regular coating. In addition, applying several layers also entails a higher paint consumption. Nevertheless, fire-resistant coating is a necessary and sustainable investment for the long term that increases safety! We are happy to help you with this.

The application of fire-resistant coatings must be done in accordance with the regulations and quality standards. We can take care of this for you at a production location or at your location after the product has been mounted. After completion of the work, an external party will issue you a certificate. In this way, your building will soon meet all the requirements again. We are available for:

From industrial areas to office buildings, we come everywhere to coat steel fire-resistant and thus increase safety. We also carry out the pre-processing on site. On location, we prepare the steel surface for the coating for optimal adhesion. The preservation is then professionally applied.

As a coating expert, we are specialized in repairing damage on location. We not only apply fire-resistant coatings, but also repair damage. When damage has occurred, the fire-resistant effect is reduced. That is why we come on location to protect the object again and thus extend the life of the steel product. We do this for various coatings on metal products. Would you like to have damage repaired at a metal preservation facility at your location? Request a no-obligation quote.

A fire-resistant paint naturally has a grayish tint. To embellish this even more, the coating can be provided with any desired RAL color. Sometimes an extra top layer is even necessary, for example because the steel is located outside. This extra striking top layer makes the steel construction even more eye-catching, which provides an extra value to the building!

Curious if we can do something for each other or is there a specific question or challenge for us? Request a quote quickly and we will be happy to help you. Whether it concerns applying a fire-resistant coating to steel or repairing damage, our goal remains the same: NESTcoat always ensures that the steel construction is fire-proof on site and the building meets all quality standards.