It all started on a production location in the metal industry for NESTcoat. And that is where the majority of our team is still active. We provide various services in the field of various hot-dip galvanizing plants, (powder) coating plants and other production companies in the Netherlands.

The unique service that we provide at production locations is what we call coating preparation. This is a traditional trade that takes place between hot-dip galvanizing and powder coating or wet painting.

After the product leaves the zinc bath, the zinc layer is not yet even. If you powder coat or wet paint it without further processing, the imperfections will become even more visible afterwards. Coating preparation thus improves the aesthetics of the final product. In addition, this processing also ensures that the coating forms a better protective layer. Sharp points are removed. These could otherwise pierce through the (powder) coating layer, causing the steel surface to not be fully protected.

We smooth out the unevenness of the zinc layer according to our own guideline. There is now a standard for this! Produced in consultation with the NEN (the Royal Netherlands Standardization Institute) who connect parties and stakeholders and ensure that they reach agreements in standards and guidelines and stakeholders to establish this standard.

We apply powder coating in any color the customer desires. Different types of coatings are also possible, such as metallics and multi-colored coatings. Powder coating is environmentally friendly as no thinners and solvents are used!

In addition to applying a powder coating, repairing damage to a powder coating is also one of our services. For example repairing construction damage before completion or repairing railings of bridges. We repair a powder coat layer without an oven by repairing the weak spots with a special wet paint.

Prevention of damage is of course always better. That is why we also carry out periodic maintenance on powder coatings. We remove dirt from the surface that causes corrosion. A clean surface not only keeps the powder coating sleek, it also protects better. During a maintenance service, we also carefully check whether there is damage to the powder coating that could further weaken the preservation. If this is the case, we will report this so you can have it repaired in consultation.

Sometimes we encounter serious damage to the preservation or a coating that has been poorly maintained for a long time, causing the metal surface to be structurally damaged. This is where our renovation service comes helps out. For each project, we look at the best way to renovate the powder coating so that it is optimally protective again.

So we offer a full powder coating service, at every stage of the coating. Would you like to have a powder coating applied to a product, do you have damage or are you interested in our maintenance service? Request a quotation!

Would you like to receive a quotation on behalf of a company? Click here and simply follow the steps to request a quotation.

Do you have a conservation problem in or around your house? Request a quotation for private individuals here.

Besides powder coating and preparation for coating, we also provide other in-house services. Like post-processing.

If hot-dip galvanized steel does not need to be coated, it sometimes has to undergo further treatment before the product can actually be used. We take this off your hands. Consider the following post-processing:

We can also carry out assembly or pre-assembly for you. Such as work that follows after the hot-dip galvanizing or the organic coating process (powder coating or wet painting).

By taking over these activities from you, your company can focus on the other processes, resulting in a higher degree of efficiency in your production process. This gives your company more production capacity and a faster delivery time.

A lot is possible in consultation. Consider the following activities:

We visit the location to inspect the condition of the metal preservation.

More informationWe help you with the set up of a plan and the implementation for periodic maintenance of metal preservation.

More informationRust, scratches, dullness or other damages to the metal surface? NESTcoat provides an aesthetic and durable recovery. We do this everywhere in the Netherlands and beyond.

More informationAre you up for something new? We restyle your metal products in exactly the color and style you want. A lot is possible with us.

More informationWe make your metal preservation as good as new again. With the renovation service, we completely restore surfaces. You can choose the look.

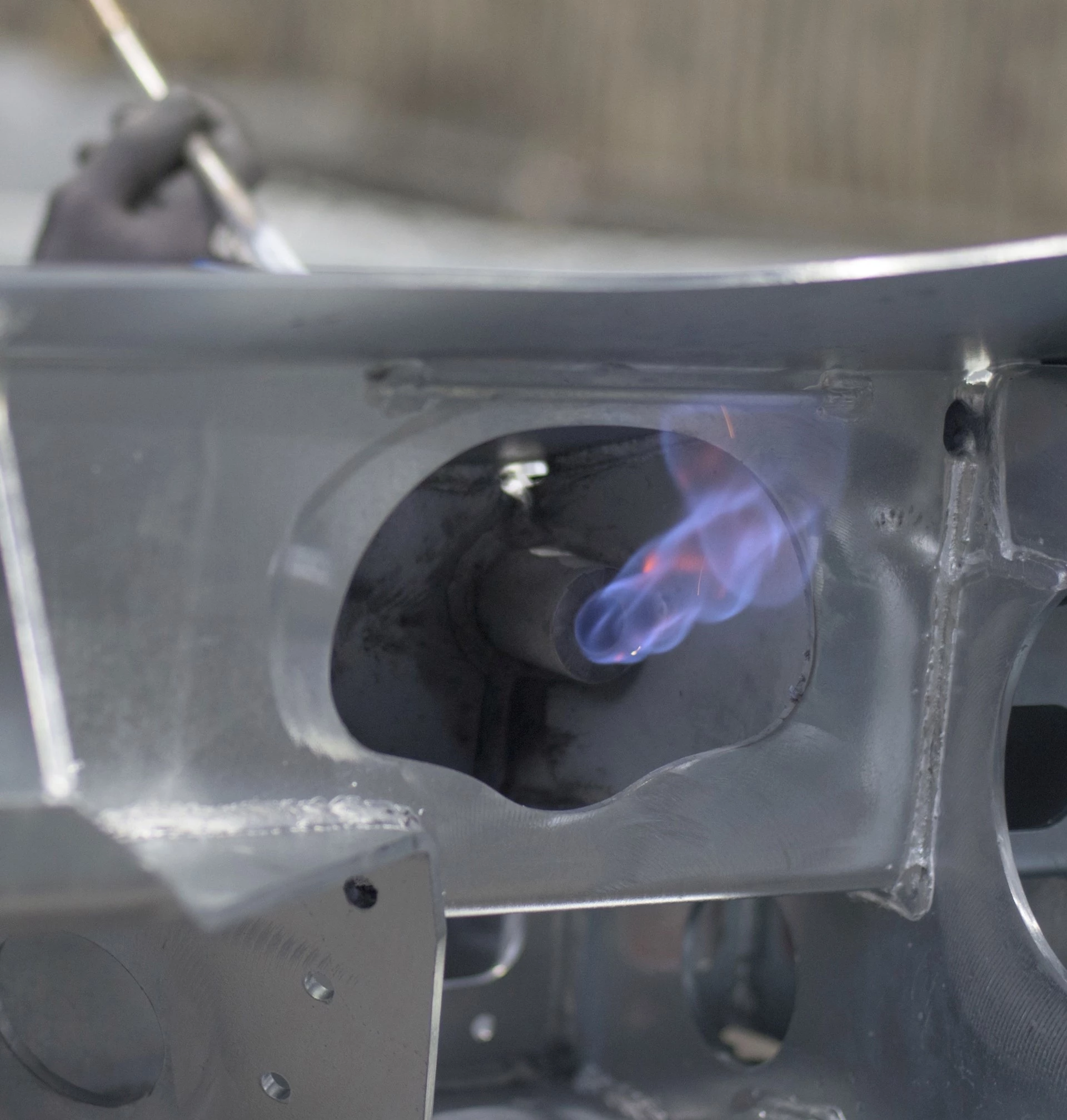

More informationWe apply fire-resistant coatings and can repair them on location for safety and permit maintenance.

More information